If you’re short on time and want a straight answer, here it is: choose spray foam when air sealing, moisture control, and year-round comfort are top priorities or when access is tricky. Choose fiberglass when upfront cost and speed are the main concerns and you can pair it with good air sealing. Below you’ll find a simple comparison, the key tradeoffs, and clear recommendations by scenario so you can make the right call for your home or business.

At-a-Glance Comparison

Numbers are typical ranges. Real-world performance depends on building design, installation quality, and local code requirements.

The 60-Second Verdicts By Scenario

Attic comfort and draft reduction:

Spray foam at the roofline is the winner when you want a tighter, more comfortable home with fewer hot-and-cold swings. If you’re cost sensitive, blown-in fiberglass on the attic floor plus thorough air sealing is a solid alternative.

Crawl spaces and rim joists:

Walls during remodels or tenant improvements:

Metal buildings and warehouses:

Irregular cavities and tricky access:

Cost Today vs. Savings Tomorrow

Upfront cost:

Lifetime value:

A smart compromise:

What Really Drives Comfort and Bills: R-Value + Air Sealing

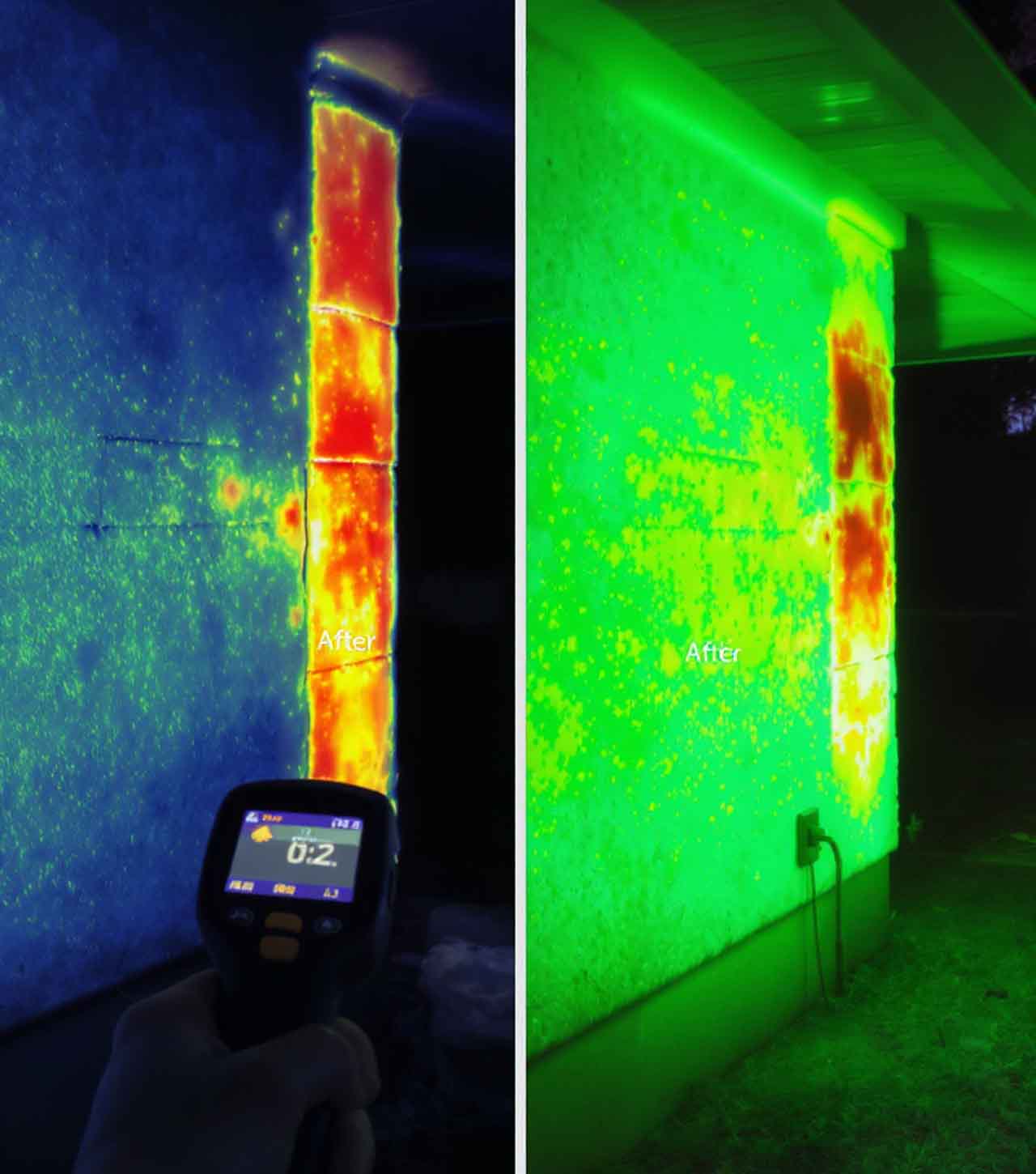

R-value measures resistance to heat flow, but it does not stop air movement. Most comfort complaints come from air leaks carrying heat and moisture through the building shell. Spray foam combines insulation with strong air sealing in one step, so its real-world performance often exceeds what a simple R-value comparison suggests. Fiberglass delivers rated R-value when perfectly installed, but you still need dedicated air sealing to prevent drafts and keep that R-value honest.

Bottom line: If you improve air sealing, you improve comfort and energy efficiency quickly. Spray foam bakes air sealing into the install. Fiberglass needs a separate air sealing pass for similar results.

Moisture, Mold, and Building Health

Moisture travels with air. That’s why a leaky attic, wall, or crawl space can lead to condensation and mold risk even when the insulation looks thick. Closed-cell spray foam acts as both an air barrier and a class II or class I vapor retarder depending on thickness, which helps manage moisture in rooflines, rim joists, and crawl spaces. Open-cell foam is vapor permeable and is useful when you want assemblies to dry toward the interior. Fiberglass does not stop moisture-laden air, so you must integrate air sealing and the right vapor control strategy for your climate and assembly.

Rule of thumb: Where you expect moisture pressure or temperature swings, prioritize airtightness and the correct vapor profile. Spray foam simplifies that. Fiberglass can work well when the air sealing and vapor control details are thoughtfully executed.

How To Choose Quickly

Ask these five questions and follow the guidance that fits:

1. What is your top priority?

- Maximum comfort and leak control → Start with spray foam.

- Lowest upfront cost → Fiberglass with a strong air sealing plan.

2. Where is the work happening?

- Roofline, rim joists, crawl space, metal building → Foam leads.

- Open stud walls or an attic floor with easy access → Fiberglass can be very efficient.

3. Is moisture a concern?

- Condensation on roof decks, damp crawl spaces, or metal skins → Closed-cell foam is often the safest bet.

- Dry interior walls with normal humidity → Either can work depending on budget.

4. Is noise control important?

- Bedrooms over living spaces, office demising walls, multi-family partitions → Open-cell foam or well-installed fiberglass batts both help, with a slight edge to foam in tricky cavities.

5. What is your timeline?

- Need it fast with minimal disruption → Fiberglass is quick in open areas.

- Willing to plan for a pro foam install window for better long-term performance → Spray foam.

Common Mistakes to Avoid

R-value only thinking:

Compressing batts:

Skipping ventilation checks:

Covering up without inspection:

Choosing foam type by price alone:

Quick FAQs

Is spray foam safe once cured?

Yes. Professional installations are ventilated during application. Once cured, the material is inert.

Can fiberglass meet code and perform well?

Yes, when it’s paired with thorough air sealing, proper fit, and the right vapor strategy. Installation quality matters.

Can I mix materials?

Absolutely. Many projects use closed-cell foam at rim joists or crawl spaces for control, and fiberglass in walls or attic floors to optimize cost and comfort.

Which foam do I need?

- Closed-cell: Higher R per inch, strong moisture resistance, added rigidity.

- Open-cell: Great for sound control and air sealing in interior assemblies, allows drying.

The Bottom Line

Pick spray foam when you want the best combination of insulation and airtightness, when moisture control is critical, or when your building has hard-to-seal geometry.

Pick fiberglass when you need a cost-effective, quick install and you’re prepared to invest in thorough air sealing and proper detailing.

For many projects, a hybrid approach delivers the best value: foam where control is critical, fiberglass where access is easy and conditions are dry.

Ready To Choose With Confidence?

Insulation Solutions provides expert assessments and pro installation for homes and businesses across Northern California, including the Bay Area, Sacramento Valley, and the Tahoe corridor. We’ll evaluate your building, identify the biggest comfort and efficiency wins, and propose the right material in each area.

Thinking about attic insulation, crawl space upgrades, or a metal building project? Ask us about targeted foam plus fiberglass strategies that balance comfort and budget. Contact Insulation Solutions today for a free, no-pressure estimate.

0 Comments